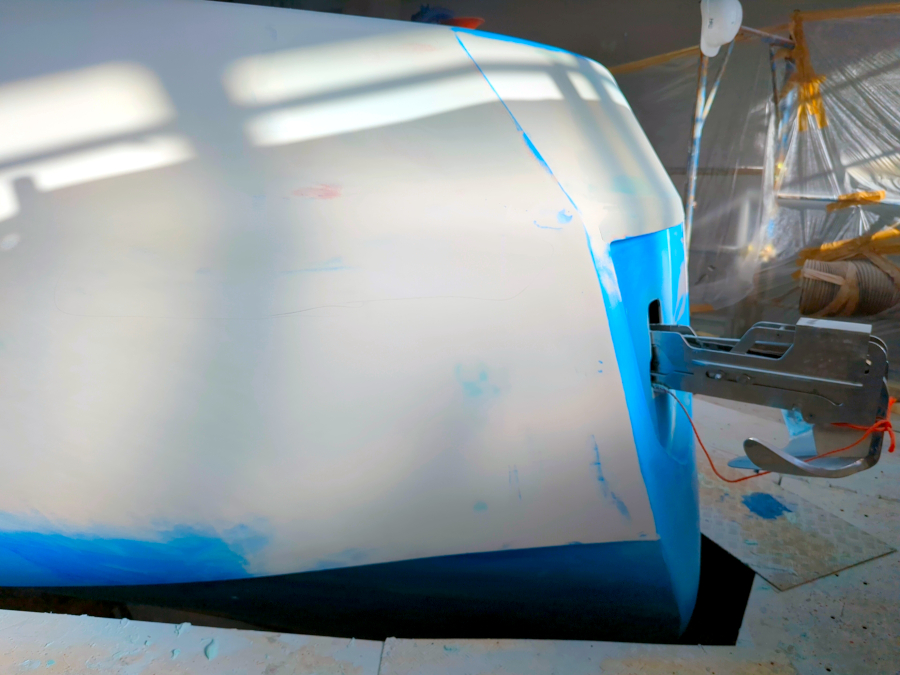

Il Forte 47 nella versione GranTurismo

West Navaltech moves from workboats to yachting with Forte Yachts

At the 2025 Cannes Yachting Festival, PressMare met the team of West Navaltech, parent company of the new brand Forte Yachts: Fernando Moricca, co-owner and business manager; Livio Franchini, co-owner, sales and production manager; and Giacomo Lombardi, USA sales manager. Together with them and with Paolo Giordano, the yacht designer behind the Forte 47, we retraced the company’s origins, its experience in the workboat and shipbuilding sectors, and the launch of its first yacht – designed on a naval architecture by Umberto Tagliavini. Currently nearing completion, the launch of the Forte 47 is scheduled for November 2025.

PressMare – Let’s start from the beginning: what is West Navaltech and how was it founded?

Livio Franchini – West Navaltech is the company that owns the Forte Yachts brand. Fernando and I founded it in 2020 with his family. I come from a naval background: I studied engineering in Genoa, worked first in the leisure boating sector and then for many years in the workboat and military segments.

Fernando Moricca – I met Livio at the very beginning of his professional experience. My family has always been involved in international trade, particularly in yacht sales. In 2020, with Livio’s contribution, we decided to found the company with two business lines: the design and production of workboats in steel and aluminum up to 24 meters, and subcontracted metal and mechanical fabrication.

PM – What were the first projects you developed?

LF – Over these five years we’ve grown considerably, thanks also to the support of our partners who purchased the production facilities in Ameglia, near La Spezia, and equipped them for West Navaltech. We built a 14-meter harbor tug, four aluminum river passenger launches, and later collaborated with STEM Parma on twelve vessels for the Italian Fire Department, managing the entire order — from outfitting to sea trials.

FM – Another major milestone was our first electric catamaran, built in aluminum for an American company that will operate it in the Red Sea. It was tested just a few days ago with the owner. For us it’s an important achievement: our first fully electric boat. The client requested a full-electric system, and we partnered with Imecar (Turkey) for the battery packs and control logic, and Tema (Croatia) for the motor, inverter, and battery management software.

PM – What’s your experience in marine carpentry?

FM – Excellent, I would say. In recent years we’ve produced over 60 transom doors for yachts from 35 to 60 meters, working directly with Sanlorenzo — for example on the Alloy 44 — and with companies such as Motomar, PinCraft, and GB Mec. Sometimes we design in-house; other times we handle only the fabrication.

LF – We have a well-equipped carpentry department and have specialized in aluminum construction. We’ve also built hulls as subcontractors for Novamarine and STEM, and we’re currently building a 16-meter vessel for a Genoese yard serving the port authorities of Livorno. We also manufacture rudders for CMC Marine — it’s a sector we’ve cultivated with care and passion.

PM – Then you decided to enter the leisure sector with your own brand. Why?

LF – About a year and a half ago, we decided to diversify. On one hand, to separate two sectors that often follow opposite trends — when the workboat market grows, the leisure sector slows, and vice versa — yet can complement and coexist within the same company. On the other, because we wanted to create our own product, built around our ideas.

Being only subcontractors can lead far, but it’s limiting. I’m 40 and wanted to create something of our own — for today and for the next thirty years.

FM – It wasn’t easy, but we decided to invest heavily right from the start, even before officially announcing the project. We put ourselves out there personally, also in terms of communication: we’ve produced videos where we talk about the boat ourselves, now being published on our YouTube channel.

THE DESIGN OF THE FORTE 47

PM – Let’s talk about your first model, the Forte 47.

Paolo Giordano – Our goal was to create a yacht designed for conviviality, with generous, livable spaces and strong, distinctive lines. Thanks to aluminum, we were able to push the design of the transom and side openings, creating a striking living area. We like to define the Forte 47 as a “mini superyacht”, with volumes and surfaces rarely found in boats of this size.

PM – Why build in aluminum?

LF – We chose aluminum both because of our know-how and because it positions us in a higher market segment. But it’s not just about the material: for the interiors, for instance, we adopted a different approach than many competitors, starting with a full-scale mock-up, a method typical of the superyacht world.

In this phase, we were supported by Genesis Interiors (Viareggio), which built the interiors of the Forte 47. During construction, we relied on suppliers specialized in large yachts — fairing, painting, and interior finishing — to deliver a luxury boat distinguished by the quality of craftsmanship it expresses.

FM – The naval architecture is by Umberto Tagliavini and West Navaltech. Tagliavini has believed in us from the very beginning: just twenty days after we founded the company, he convinced a client to award us our first order — the 14-meter tug mentioned earlier.

PM – What are the most remarkable features found on board the Forte 47?

PG – One of the most distinctive features is the pair of large 6-meter side doors, which, when open, create a unique beach area. They’re positioned about one meter above water level — low enough for easy use, yet high enough to avoid slamming in waves.

With the doors open, the total beam reaches 6.3 meters, providing around 40 square meters of living space. Thanks to the full-beam superstructure — the hull has a maximum beam of 4.5 meters — the interiors are remarkably spacious.

LF – The interior layout includes two real cabins, a strong point that differentiates us from many boats of similar size.

PM – What versions and propulsion systems are planned?

FM – There will be two versions: the Lounge Deck, with IPS propulsion, ensuring excellent performance and a larger swim platform thanks to a recessed transom; and the Gran Turismo, with outboard engines. We believe strongly in outboards — they offer practicality and layout freedom. Currently, market interest is roughly 60/40 in favor of outboards.

PG – We conducted extensive testing and evaluations. Some markets, such as the U.S., are already mature for outboards; Europe is following quickly. We didn’t want to exclude any option, so the owner can freely choose.

LF – The standard equipment is high-end: Quick stabilizer, Kohler generator, Garmin electronics with dual 22-inch displays. We selected premium suppliers to ensure genuine — not just perceived — quality. For example, we installed Sleipner bow thrusters, which already offered full software integration with Mercury systems at the time of purchase.

PM – What’s your growth strategy?

FM – We’re not aiming for large production numbers — that wouldn’t align with our capacity or product philosophy. We prefer to grow progressively.

We already plan to expand the range with larger models of 58 and 69 feet, designs that remain manageable within our facilities. Our current production limit is around 24 meters: up to 22–23 meters, we can build and launch directly on the Magra River.

Giacomo Lombardi – From a commercial standpoint, we’re focusing closely on the U.S. market. At Genesis Interiors, the company developing our interiors, we have offices both in Viareggio and Fort Lauderdale, which gives us a direct bridge to the United States.

PM – What will be Forte Yachts’ distinctive hallmark?

FM – We aim for the high-end market, but not just in price: we want to justify that positioning with technical solutions, innovative design, and build quality.

This isn’t serial production — it’s tailor-made craftsmanship, drawing on our experience in workboats and marine carpentry to create exclusive yachts for leisure boating.

©PressMare - All rights reserved