Royal Huisman 408 AQUARIUS II - photo by Tom van Oossanen AVV7367c

Rondal delivered some creative solutions to the Aquarius II

The 65-metre Dykstra designed ketch Aquarius II will be one of the stand-out performance superyachts of her generation when launched next year. She is currently in build at the Royal Huisman shipyard in the Netherlands, with Rondal closely involved from conception to provide expertise in the design, engineering and fabrication of sailing systems and composite structures.

‘The loads aboard Aquarius II are high and present some interesting challenges,’ says Rondal’s lead project engineer Edoardo Volpe. ‘Yet Rondal’s reputation is built on resolving challenges. We have already built three impressive 70m-plus rigs in recent years and we are currently preparing a rig for an 85m sloop, which will become one of the world’s largest. So we are comfortable with the load levels of this ketch. What is special about this yacht is the combination of needing a very high-performance rig for regattas – even more than Aquarius I – combined with the owner’s requirement for it also to be a family cruising boat that can be handled by a small crew.’

The solution developed by Rondal is a mast that’s almost as tweakable as that of a super-maxi. Unlike Aquarius I, the new boat doesn’t have checkstays. Instead, deflectors on the main backstays are used, which the racing team ‘can adjust and optimise the sail shape as much as they please,’ Volpe adds. ‘Even the mizzen forestay tension can be adjusted.’

Yet, at the same time, the boat needs settings that can be locked down as far as possible for absolute ease of handling when cruising. Determining values that would work across all wind strengths and sea states was a complex task, especially considering the number of parameters involved. Volpe says this ‘involved a lot of time in simulation, trying to get the right settings for cruising mode while still delivering a lightweight rig with the response and mobility needed for regattas.’

Aquarius II is being built for an experienced superyacht owner who also likes the regatta aspect of his current yacht – the 56m (184ft) Aquarius I from 2019. During her regatta debut at the St Barths Bucket Regatta, she finished first in “Les Elegantes” Class. And in 2022 she was winner in class again. The spirit of tradition styling of both yachts disguises great performance and Aquarius II will be even better.

Having been freed from the usual Panamax restrictions on air draught she will be a veritable wolf in sheep's clothing, sporting a single piece 67.5m Rondal main mast with an air draught including equipment and flagpole of 69m. This is being produced using Rondal’s state-ofthe- art manufacturing facilities.

As with the owner’s previous yacht, Rondal worked closely with Royal Huisman, Dykstra Naval Architects, Doyle Sails and the owner’s project manager Godfrey Cray, a former, four-time Whitbread Round the World Race competitor and America’s Cup team member, who has himself been the project manager of many superyachts, right from the outset to incorporate reliable, weight-saving and performance enhancing sailing systems.

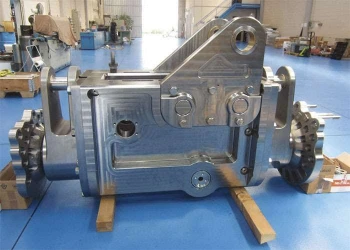

Rondal’s contribution to Aquarius II is wide ranging, including spars, the lightweight composite superstructure, the mammoth aluminium-with-carbon fibre captive drum winch systems and their associated line feeders. These aspects play pivotal roles in optimising the yacht’s performance and reliability, while minimising weight.

Given the owner’s sailing background and previous St Barths Bucket victories, it’s no surprise that the top of the list of objectives for the new yacht was “sailing performance to be commensurate with the length increase from the first Aquarius”. At the same time, the vessel needed to meet the rigorous demands of comfort and luxury that are expected in this market.

A measure of just how much larger she is than the first Aquarius is that the new boat has an astounding 45 per cent more accommodation volume. The sail area is nothing short of colossal – almost half an acre upwind (1,958m² / 21,000sq ft) and well over twice that downwind (4,671m² / 50,700sq ft).

An addition to Rondal’s normal engineering processes was that lessons learned and valuable feedback from the crew of Aquarius I, could be integrated into the first loop of engineering. That was followed by discussions with the naval architect, the rig consultant and the sailmaker to refine the sailplan, the rig geometry, sail settings and load cases.

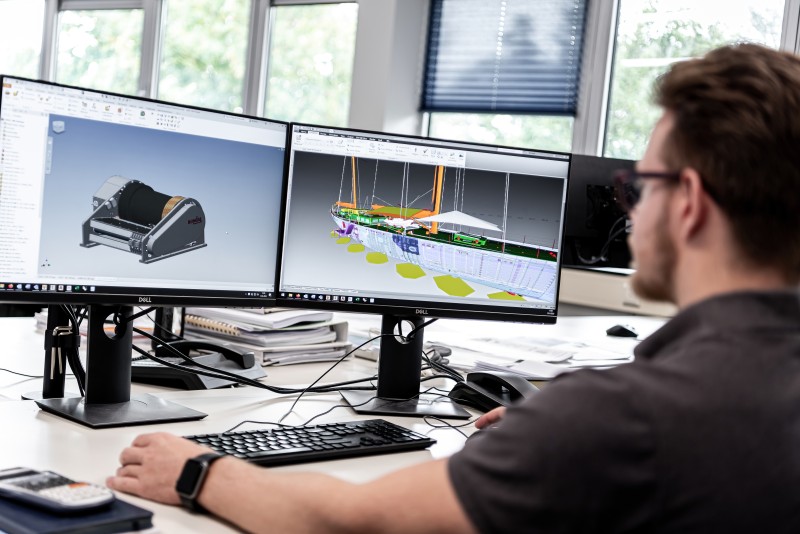

This phase also included a detailed analysis of the hydraulic power needed in different racing scenarios. Manoeuvres such as bearing away at a windward mark, hoisting the gennaker (which takes barely more than 30 seconds) and furling the blade jib were simulated with time steps. Volpe says this enabled his team to be sure that ‘the crew is able to operate the vessel quickly in all the scenarios.’

Next, a global engineering phase evaluated the spar’s structural performance and the integration of sail and rig systems. This process generated predicted loads to enable deck engineers to specify appropriate blocks and other hardware in advance of the detailed mechanical engineering phase.

Although very much a spirit of tradition yacht with gorgeous lines, proportionately low freeboard and long overhangs, taking advantage of fully tested innovations and system upgrades was also on the shortlist of five key objectives. However, any innovation included in the project had to bring tangible improvements, without adding undue weight and also had to be engineered for absolute reliability.

‘Some innovations may be seriously cool and add function and enjoyment,’ says Cray. ‘However, they can come with development, time, cost and reliability issues.’ That final point is particularly important – Aquarius I sailed an impressive 11,000 miles in the first five months after handover.

The new vessel needs to be just as capable of being pushed to the limit with a race crew of 30 people as she is easy to handle when cruising, or on delivery with a skeleton crew. As a result, Cray explains that they steered ‘away from risky innovation projects.’

The scale of this yacht is mind-blowing, making 130ft J Class yachts look positively diminutive. Most large sailing superyachts are limited by a desire to be able to pass under the Bridge of the Americas on the Panama canal. However, that requirement was waived by the owner once it became clear that revised regulations would impose a new lower limit of 62.5 metres on air draught, a figure a few metres less than the tallest rig to pass to date – see sidebar.

In subsequent consultations the owner re-stated that he wanted ‘no compromise to the sailing performance and therefore we should make no concessions for Panama’ says Cray. He also reiterated his preference for a spoon bow on similar lines to Aquarius I.

Once unshackled from Panamax constraints, the yacht’s overall length grew to 65m while air draught crept up to 67.5m for the mainmast and 60m for the mizzen. The single section carbon main mast is a masterpiece. Many years ago, Rondal predicted the ever-growing size of superyachts and the accompanying demand for mammoth spars. It therefore developed a manufacturing process capable of producing masts of almost unlimited size.

When other manufacturers were investing eye-watering sums in autoclaves – which put a hard limit on the longest spar they could produce without splitting it into multiple sections – Rondal sought to perfect an out-of-autoclave (OOA) production system. A single-piece mast represents a massive advantage, markedly reducing weight and complexity compared with a spar that must be bolted together from several lengths of carbon tube.

Today Rondal’s OOA system produces a laminate with void content similar of that of typical autoclaved spars and has been used to build spars of up to +70m. The process starts with creating several autoclaved carbon laminates over a male mould that form the shape of the mast. These are joined together in frames and eventually become part of the spar, adding structural integrity and represent around 20 per of the total laminate thickness.

Internal patching, compression tubes and conduits are inserted after the moulds are produced, before the remaining 80 per cent of the laminate is added over the full length of the mast, using combinations of unidirectional, woven and biaxial carbon composite prepreg material. During the construction, the mast section is oven cured in one piece for over 14 hours at 85°C to achieve ultimate mechanical and thermal properties.

Pre-assembly and minor fairing is carried out before painting, then tracks, halyard locks, instruments and other equipment are all carefully mounted.

Development of Aquarius II’s sail handling and sailing systems by Rondal, Doyle Sails and Royal Huisman began at the inception of the project. The involvement of Doyle, which dominated in the last St Barths Bucket, was a critical factor for structural engineering and development of control systems, as Doyle’s load-sharing structured luff sails massively reduce some loads, especially in the headstay and backstays.

Nevertheless, there’s no escaping that loads on a performance vessel of this size are enormous. Yet success – and safety – on the racecourse demands equipment that will perform flawlessly, whether fully powered up sailing close-hauled or midgybe. There’s also enormous pressure for deck hardware to be as light as possible, without risk of compromising reliability.

Aquarius II is fitted with a refinement of the performance version of Rondal’s furling boom. This includes the longrunning ability to adjust both luff and foot tension, giving complete control over sail shape, even when reefed. A cunningham is used to control the tack position at each reef, but the really neat element is Rondal’s outhaul car that automatically engages with metallic plates in the leech of the sail at each reef point. Once attached, foot tension can be adjusted in exactly the same manner as with a slab reefing sail.

A further request from both owner and crew was to create the most reliable manual back-up system possible for use in an emergency state. ‘This was only possible because we were in such really close contact with the yard,’ says Volpe. The system will work in black ship mode, even with halyard, vang or hydraulic failure. Another improvement optimised the luff track feeder to give more options for hoisting the sail without being fully head to wind.

Over the past few years Rondal has also put considerable investment into refining its captive reel winches and engineering larger models to suit the very biggest superyachts. Hydraulic versions offer working loads of up to 48 tonnes and mind-blowing line speeds of up to 75 metres per minute – a critical figure when gybing a spinnaker mid-race. There’s also an electric version that’s even faster, with 100 metre per minute line speeds. These are married to Rondal line feeders that produce a perfectly neat wrap on the drum – an essential element in creating an absolutely reliable and robust system.

A lifting keel system is at the heart of any fast superyacht – ideally draught must be restricted to 4.8m (15ft 9in) to enable access to the most desirable cruising destinations. However, from a performance perspective, optimal draught for Aquarius II is a whopping 7.6m (25ft). The only way of meeting both criteria is therefore with a lifting keel, an engineering challenge in itself at this scale, especially when an imperative is to avoid it taking up too much space that could otherwise be used for accommodation.

Rondal continues to apply expertise to new areas and is a key supplier across the superyacht world, including both power and sail sectors, to yards including Baltic Yachts, Nautor’s Swan, Vitters, Perini Navi and parent company Royal Huisman.